There are many situations that we hope never to be caught in, and one of the them is having to look upon and fix a toilet that has failed to flush… especially when it has just been used! It goes without saying that reliability here is of the utmost importance, especially in commercial applications.

Here are some key points to consider:

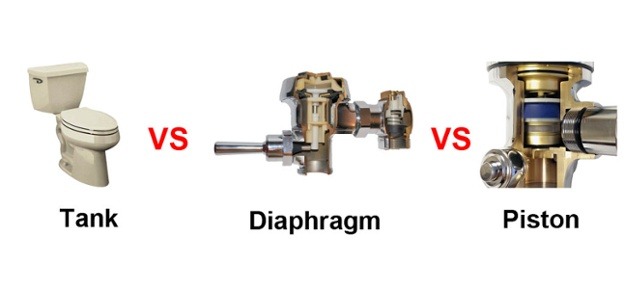

Flushers: Tanks, Diaphragms, and Pistons

As far as toilet flushers go, there are 3 prevalent technologies. Each technology was developed for a different application, so choosing the wrong one can affect how reliably it works in your lavatory. Here’s a quick rundown of each:

- Tank Flushers – Low traffic areas. These are the toilets you usually find in homes. They are also common in small offices and in places with lower water pressure.

- Diaphragm Flush Valves – Middle to high traffic areas. Best for places that see more traffic and require quicker recovery after each flush. Diaphragm valves require more water pressure (generally 20+ psi).

- Piston Flush Valves – Middle to high traffic areas. Like diaphragms, these are best for places with more traffic and require a quick recovery. However, pistons can additionally handle poorer water conditions and still run smoothly. Piston valves require 10+ psi of water pressure.

Quality of Materials

Quality products are usually made with more durable materials to be able to stand up to more abuse, human or otherwise. More metal is common in commercial lavatories, especially with piston and diaphragm valves.

Brass is a dense metal that has been preferred for commercial and industrial plumbing fittings, due to its weight and durability. Pure brass is too soft, so zinc is mixed in to harden it. However, too much zinc causes dezincification where the zinc leeches out and weakens the brass. When choosing a brass fitting, look for red brass over the yellow brass. Yellow brass will have more zinc than red brass, and subsequently be cheaper due to poorer quality.

Periodic Maintenance

Naturally, moving parts wear down from repeated use, over time. Every product has a recommended maintenance schedule that requires a relatively inexpensive repair kit. Looking at testimonials and reviews with the recommended maintenance schedule will give you an idea of which products require less time and money.

Ready, Set… Don’t Fail!

Making sure a product is made for the correct application, built of the right stuff, and doesn’t require too much upkeep is the winning formula to a blissfully functional restroom.

Any other reliability tips? Leave them in the comment section below!